Solution For Pharmaceutical Pure Water Equipment

Water is a key factor in ensuring the quality of drugs in drug production. Purified water used in medicine has very strict requirements for water quality, and it must meet the quality standards specified in the pharmacopoeia like other raw and auxiliary materials used in drug production.

In the pharmaceutical production process, many enterprises need to use purified water as raw material to produce drugs. Water is a key factor in ensuring drug quality in drug production. Purified water for medicine has very strict water quality requirements. Due to the presence of many impurities in ordinary water, including suspended solids, colloids, organic matter, microorganisms, etc., it cannot meet the needs of drug production. The preparation of purified water is a process of removing impurities from water and preventing pollution, which improves product quality by enhancing water quality.

Advantages of purified water equipment in the pharmaceutical industry

1. The quality of the produced water meets the requirements of relevant pharmacopoeias and operates stably;

2. Multiple disinfection methods are available: activated carbon pasteurization, CIP cleaning system, distribution system ozone sterilization, distribution system pasteurization;

3. Single and dual pipeline design: The production and return water circulation pipelines operate separately, reducing blind spots in the system and avoiding microbial growth;

4. New flow meter instruments and sampling valve switches, convenient for inspection, operation, and sampling hygiene;

5. Preferred quality accessories processing and manufacturing, material selection emphasizes quality, advanced processing technology manufacturing;

6. Intelligent electronic control system reduces mechanical failures and is safer;

7. Equipment manufacturing and production drawings are standardized, streamlined, and ensure equipment quality;

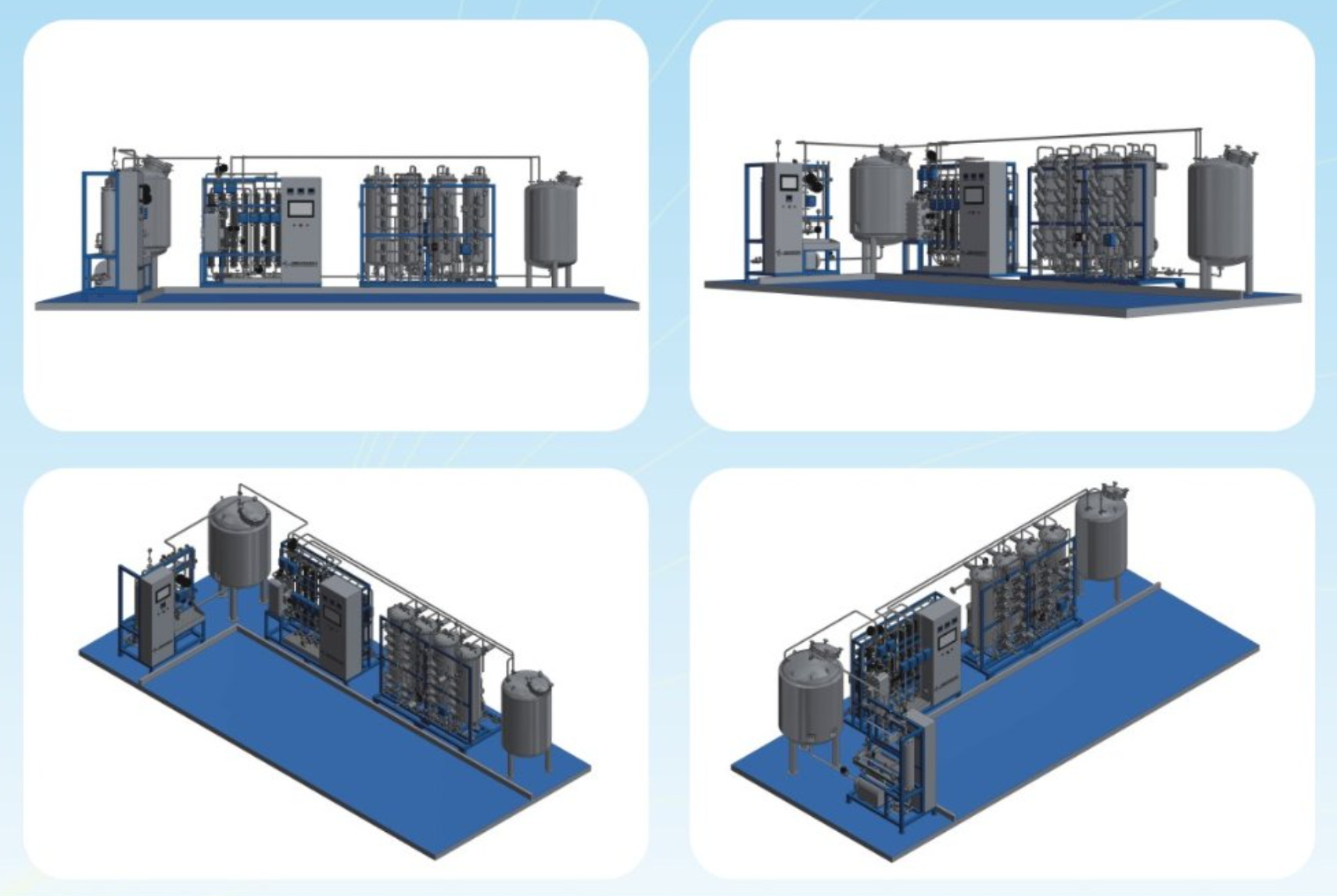

8. Patented process design, small footprint, easy operation and maintenance.

Heshuo Pharmaceutical Water Integrated Solution

Purified water is one of the raw materials used in various industries such as food, beverage, hospital, cosmetics, biology, pharmaceuticals, and cell culture. It is involved in the entire production process, including raw material cleaning, production, ingredient preparation, and formulation. Purified water is a crucial component in the production process. Our company's purified water products can be customized according to the actual size of the equipment at the customer's site. Reasonable design and provision of floor plans and 3D layouts, strictly in accordance with the latest pharmacopoeia GMP, EU, and FDA regulations and standards. Provide more reasonable products for each customer.